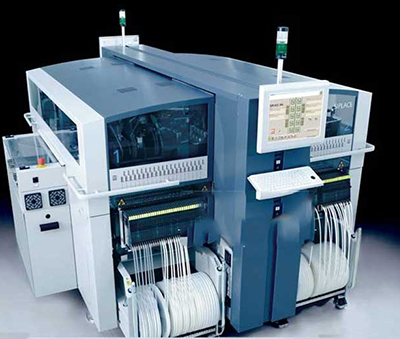

Product Features:

Siemens placement machine X3S provides customers with the highest speed, lower dpm, stable 0201 (metric) processing capability, non-stop line setting conversion and rapid new product introduction and other functions. The SIPLACEX series has a modular cantilever function and can provide 2, 3 or 4 cantilevers.

SIPLACE X3S technical parameters:

Number of cantilevers: 3

IPC speed: 78,100cph

SIPLACE Benchmark: 94,500cph

Theoretical speed: 127,875cph

Machine size: 1.9x2.3m

Placement head features: MultiStar

Component range: 01005-50x40mm

Mounting accuracy: ±41μm/3σ(C&P)~±34μm/3σ(P&P)

Angular accuracy: ±0,4°/3σ(C&P)~±0,2°/3σ(P&P)

Maximum component height: 11,5mm

Mounting force: 1,0-10 Newtons

Conveyor belt type: single track, flexible double track

Conveyor mode: asynchronous, synchronous, independent placement mode (X4i S)

PCB format: 50x50mm-850x560mm

PCB thickness: 0,3-4,5mm (other sizes can be customized upon request)

PCB weight: 3kg more

Component supply and material supply

Feeder capacity: 160 8mmX feeder modules

Feeder module type:

SIPLACE component cart, SIPLACE matrix tray feeder (MTC) 4, waffle tray tray (WPC5/WPC6) 4, JTF-S/JTF-MSIPLACE,

X feeder, Tray plate, vibrating tube, vibrating feeder, customized OEM feeder module

Pickup rate: ≥99,95%

DPM rate: ≤3dpm

Lighting level: Level 6 illumination