Can be used for flip chip (FC) and chip (DA) placement

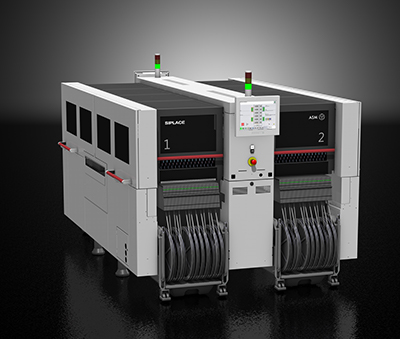

Integrate future high-growth technologies such as Flip Chip (FC) and Die Attachment (DA) into your SMT production with SIPLACE CA, a high-speed placement platform that allows you to flexibly mount components directly from the wafer. Perform bare chip placement combined with traditional feeder-based SMT placement. Your competitive advantage: New, future-oriented applications can be implemented on one SMT production line without any additional special processes. It is the ideal machine for "advanced packaging" applications. Another advantage: for all other jobs, the SIPLACE CA can be used as a powerful "normal" SMT placement machine

Highlights of SIPLACE CA:

Four SIPLACE SpeedStar placement heads support high-precision placement, placing up to 126,000 SMT components, 46,000 flip chips or 30,000 bare chips per hour

Component supply from carts or feeders or wafer diameters from 4 to 12 inches via the SIPLACE Wafer Feeding System (SIPLACE SWS)

Die Attach and Linear Dip Modules

High-precision bare chip placement, supporting embedded wafer-level ball grid array

New feature: placement accuracy up to 10 µm @ 3 s

New feature: Can handle larger boards up to 850 mm x 560 mm (long board option standard monorail)

New feature: only 2 meters long (20% shorter than before)

New feature: Can be equipped with SIPLACE MultiStar

New feature: Minimized placement pressure of only 0.5 N

New feature: Improved ease-of-use Flux detection of linear dips via imaging system, with support for multiple dips of different thicknesses simultaneously on the same dipping late