Panasonic DT401-F placement machine

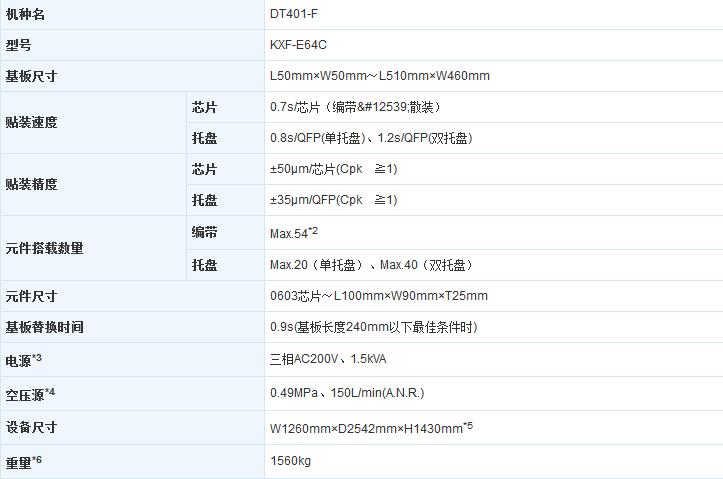

Panasonic DT401-F multi-function placement machine parameters

Detailed description of Panasonic DT401-F placement machine

1. The Panasonic DT401 is a direct pallet modular, multi-function placement machine designed to give users the flexibility to place large numbers of different, odd-shaped components at high speeds.

Direct placement head pick-up allows for a wide range of components, while pallet feeder replenishment and feeder collection exchange carts provide improved operating rates.

2. Can handle various parts from microchips to large parts, such as BGAs, CSPs and connectors

3. DT401 handles a wide variety of components, including 0402 chips, BGAs, CSPs, connectors and others with a larger thickness of 100 mm x 90 mm (25 mm) for large components. To ensure this flexibility, the machine supports five belt feeders with variable feed spacing functionality. The DT401 uses the same feed table and feeder as our CM402, resulting in cost savings, reduced feeder inventory, and increased flexibility and interchangeability.

4. Load control heads provided as standard configuration, the maximum load generated by the three load control head series is 50 N, which allows almost all plug-in connectors to be installed.

Panasonic DT401-F SMT Features and Benefits

Direct picking and dynamic component replenishment and changeover allow for high-speed production

Supports dual-pallet and single-pallet feeders

8 mm dual-belt feeders, and 12/16, 24/32, 44/

Interchangeable platforms for 56 and 72 mm belt feeders

handle boards up to 510 mm long x 460 mm wide

Achieving the ability to cope with various components and high-precision placement

Corresponding to the modular multi-function placement machine for direct suction trays