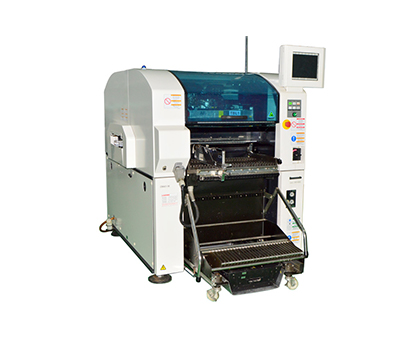

Panasonic placement machine CM401-L: Compact structure, high productivity per unit area.

Through the development of a high-speed multi-function placement head and a high-speed and high-precision identification system, ultra-high-speed, high-precision placement is achieved.

At the same time, the small and compact body structure, Can take advantage of space saving.

The intelligent material rack

can adjust the feeding distance.

Through the memory function of the remaining components, the material can be replenished in time.

When using 8 mm material tape, up to 108 types can be loaded.

According to the product and productivity, you can choose the best placement head machine Type name CM401-L

Substrate size L 50 mm × W 50 mm ? L 510 mm × W 460 mm

High-speed placement head 8 nozzles

Mounting speed 0.12 s/chip (Type A)

Mounting accuracy ±50 μm/chip ( Cpk≧1)

Component size 0603 chip? L 24 mm × W 24 mm

Multifunctional placement head 3 nozzles

Placement speed 0.42 s/QFP (B type)

Placement accuracy ±35 μm/QFP (Cpk≧1)

Component Size 0603 chip? L100 mm × W90 mm

substrate replacement time 0.9 s (substrate length 240 mm or less under better conditions)

Due to different operating conditions, values such as placement cycle time and placement accuracy will change accordingly.

See specifications for details

Not compatible with shuttle tray feeder

Compact structure and high productivity per unit area

Through the development of high-speed multi-functional placement heads and high-speed, high-precision identification systems

Ultra-high-speed, high-precision placement is achieved.

At the same time, the compact and compact body structure can take advantage of space saving.

Intelligent material rack

Five types of tape racks correspond to all previous tape racks

That is, the company's original (CM201) 66 species -> concentrated in 5 species;

Adjustable material spacing

Through the memory function of the remaining components, timely replenishment is reminded.

When using 8MM tape, up to 108 types can be reproduced