Topco vacuum reflow soldering TOP-F1030DL product featuresFeatures

1. For vacuum SMT welding of automotive headlights, aerospace, aviation, medical, automotive, BGA, FPC, LED, etc.

2. Adopt industrial embedded control system. The system uses dual CPU operation and can run independently from the computer (computer crashes). It is not only stable and reliable, but also has better temperature control.

3. The same specifications and models are the most available, supporting dual-rail speed, dual-rail single cavity, dual-rail dual cavity, and dual-rail multi-purpose.

4. The upper furnace cover of double-track double-cavity and double-track single-cavity lifts horizontally simultaneously, making maintenance and repair more convenient.

5. The equipment supports the recipe function of key welding parameters and supports MES remote data reading.

6. Step-by-step vacuuming design, vacuuming can be done in up to 5 steps.

7. The patented sealing ring water-cooling structure not only has a longer life and lower usage costs, but also reduces expensive product damage caused by poor sealing.

8. The maximum vacuum degree can reach 0.1KPa, Void Single<1%, Total<2%.

9. The fastest cycle time is 30s/per cycle, and the vacuum reflow soldering industry is more efficient.

10. The heating time is about 30 minutes.

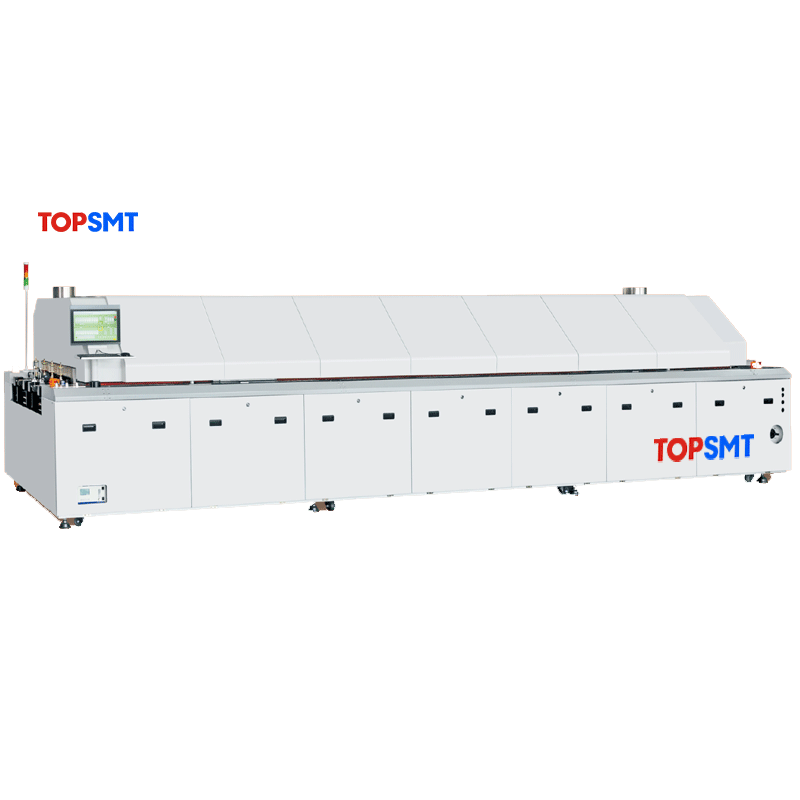

TOP-F1030DL technical parameters Specifications

Equipment model: HX-F1030DL

Equipment size (mm): L7100*D1680*H1500

Machine weight: about: 3500KG

Number of heating zones: 10 upper and 10 lower heating zones

Number of cooling zones: 3 up and 3 down, a total of 6 cooling zones

Cooling method: forced water cooling

Exhaust air requirement: 3 10m /H*2

Void rate: about: 1%-2%

Power requirements: 3P 380V/220/480 50/60Hz

Total power: 85KW

Sectional starting power: 50KW

Power consumption: about: 13-20KW

Hot air blower speed regulation: frequency converter

Heating time: about: 30min

Temperature control range: room temperature~300℃ can be set

Production formula: multiple combinations of production formulas can be stored

Track structure: double track

Vacuum structure: double-track single cavity (single-sided vacuum)

Vehicle size (mm): L400*D250

Conveyor belt height (mm): 900±20

Transportation method: chain drive

Lower vacuum pressure: 0.1KPa

Vacuum pump flow: 1000L/min

Pressure relief time: ≤10s

Production efficiency: ≥40S

Nitrogen structure: full/partial nitrogen filling

Nitrogen system: automatic or manual switchable

Nitrogen consumption: about: 700L/min