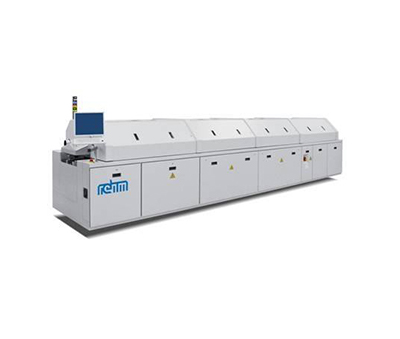

German rehm reflow oven

Introduction to German REHM reflow oven :

1. The main products of REHM V7 reflow oven are V7-Pro and V7-Extra.

2. The heating length of V7-Pro is 3.3m and the total length is 6.2m. The heating length of V7-Extra is 3.8m and the total length is 6.5m.

3. Full high-quality stainless steel furnace

4. High-quality transmission device (guide rail), divided into single rail (single central support), double rail (double central support); there are also guide rails that coexist with mesh belts

5. Computer controlled oil injection system, oil can be injected to every point

6. Oxygen content can be <100ppm

7. Working electric power is less than 16KW (V7-Extra 6.5m)

8. German original low-energy consumption high-temperature motor with self-heating function (same as ERSA);

9. High-efficiency flux recovery system (recycling efficiency up to 98%), no need for downtime and maintenance

10. Horizontal reflow design, the temperature difference between the constant temperature zone and the reflow zone is >=120 degrees

11. Computer motherboard production flow rate>1.2M/minute

Heating system

Transmission system

Transmission speed: The conveyor belt and track have separate control systems.

Conveying protection: When an alarm occurs, the conveying system can be driven directly at full speed, and the product will automatically be output at the fastest speed to avoid damage.

The track adopts special super alloy rails and an automatic lubrication system, which has low deformation, low wear, and no interference caused by falling boards, stuck boards, and splints.

Optional)

Flux is filtered and collected and nitrogen is recovered, Flux is fully discharged, and there will be no Flux residue in the furnace.

Shenzhen Topco Electronic Technology Co., Ltd. specializes in providing the following SMT equipment to electronic manufacturers:

MPM printing press , Koh Young SPI

Panasonic placement machine , Fuji placement machine , Siemens placement machine , placement machine rental

Meilu AOI , Vitronics Soltec reflow soldering

The entire SMT production line equipment, as well as spare parts, services and solutions.