HELLER reflow soldering is an imported reflow soldering with a higher cost performance. HELLER reflow soldering is energy-saving and efficient.

The HELLER1936MK5 system can achieve higher reproducibility through lower delta Ts. The latest breakthrough in the Mark 5 reflow oven system further reduces customers' acquisition costs. Heller's new heating and cooling improvements will reduce nitrogen consumption and electricity consumption by 40%. The MK5 series is not only a better reflow soldering system, but also has the best overall value in the industry! Innovate for your benefit.

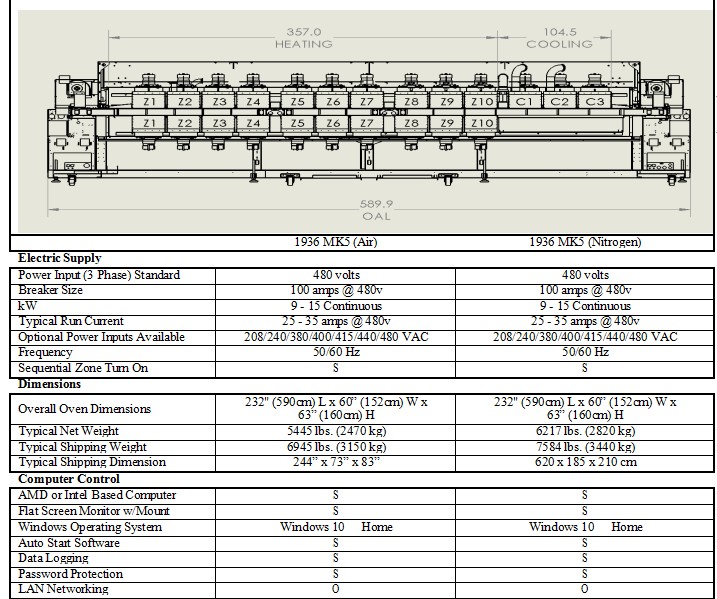

HELLER 1936MK5

Basic specifications

Lead-free applications

Easy maintenance

Save energy and nitrogen

Standard Cpk software

Heller invented the waterless/filterless flux collection system, for which he received the industry's Vision Innovation Award. But more importantly, this invention allows maintenance intervals to be extended from weeks to months. Other breakthroughs in energy management help Heller's customers be environmentally responsible while maintaining their sustainability guidelines.

MK5 series

total length

Number of heating zones/total length of heating zones

Number of cooling zones

1936MK5 reflow oven

589 cm (232 inches)

10 upper heating zones/10 lower heating zones

360 cm (141 inches)

3 upper cooling zones (standard option), lower cooling zone/external cooling (optional)