HELLER 1936MK7 adopts the latest low-top cover design, which is convenient for customers to operate and maintain. The surface temperature of the machine is lower, which is environmentally friendly and energy-saving. Vertical Baking Oven The vertical oven developed by Heller can replace the original ordinary oven and realize the automated online baking process. Through special vertical transmission, it can greatly reduce the floor space and obtain a stable temperature curve; it overcomes the inability of traditional ovens to The shortcomings of automated production, and the temperature uniformity is obviously better than that of traditional ovens; the main applications of vertical baking ovens include: chip mounting, flip chip, glue filling, COB packaging, etc.

Leading Industry 4.0 compatibility

Heller provides corresponding computer host/IoM interfaces for Industry 4.0 systems, including:

• central control system

• Product production data – number of boards produced, process parameters, production and downtime

• MTBF/MTTA/MTTR management

• Energy management and control systems

• Product traceability data

Heller cooperates with a variety of management system software to provide corresponding compatible interfaces

-CFX(AMQP MQTT)

-Hermes

-PanaCIM

-Fuji Smart Factory

-ASM

-Provide compatible interfaces according to actual customer needs

HELLER's proprietary energy management software intelligently manages energy consumption and automatically adjusts equipment exhaust air according to production status (full load, small amount or idle). Achieve energy consumption savings of up to 10~20%!

The Heller online vacuum reflow furnace can realize automated large-scale mass production of vacuum welding and reduce production costs; the built-in vacuum module can accurately extract the true temperature in five stages.

main feature:

Multi-temperature zone design, more temperature control points, to meet different temperature curve requirements

Effectively eliminate voids, the total void area can be controlled below 1%

Highly efficient production capacity, with an average production cycle of 30 to 60 seconds

High-efficiency oil-free vacuum pump unit can achieve the shortest pressure reduction time

Efficient flux recovery system to prevent flux residue

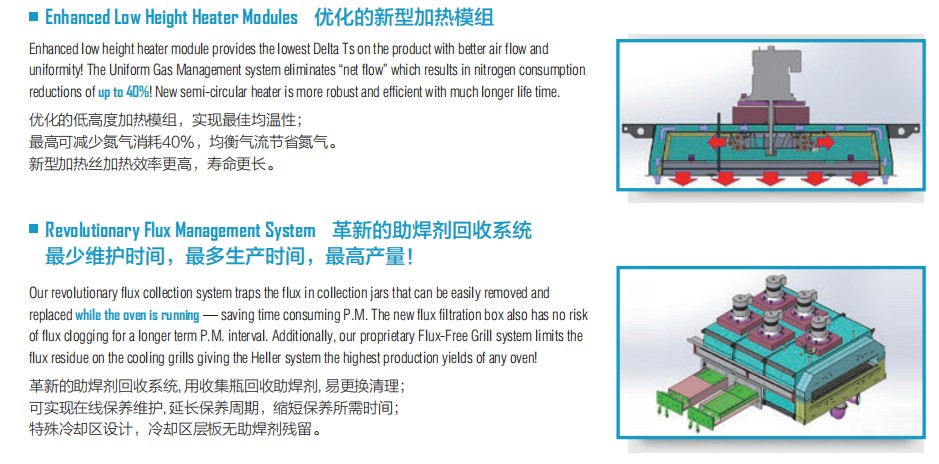

Machine size: 590 cm x 135 cm x 160 cm Heating area: 12”x10 Cooling area: 12”x3 A Better Worldreflow oven, lead-free application, low furnace height, simple maintenance, energy saving and nitrogen saving, standard Cpk software, enhanced heating module, super cooling capacity, Profile in one step.