135 1032 1270

Shenzhen Tepu Ke Electronic Equipment Co.,Ltd.

Contact: 135 1032 1270 (Miss Jiang)

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

Online Inquiry

Detailed introduction

ERSA reflow HOTFLOW 3/20 product introduction:

1. Since their introduction nearly 30 years ago, ERSA's reflow ovens have set the industry standard for high-end reflow ovens. The new third-generation reflow oven HOTFLOW 3 is developed based on ERSA multi-point nozzle heating technology. The developers of the new HOTFLOW series focused on improving the heat transfer performance of the equipment and introduced a series of improvements, including redesigned process channels, using a revolutionary multi-rail conveyor system to increase production capacity and reduce the consumption of electricity and nitrogen. consumption, improving cooling systems and optimizing process control, among others.

2. This 10-temperature zone reflow oven has an effective process length of more than 5 meters and is suitable for mass production needs.

3. For history in reflow soldering technology, ERSA's HOTFLOW series uses the revolutionary ERSA Process Control (EPC) heat transfer process control system to monitor not only the temperature of the air, but also the air flow rate. In this manner, a regular monitoring system monitors the heat transfer rate of the actual reflow process. The bottom line result is that most of Stabile's reflow technology optimizes process independent heat exchanger for tunnel load, thermal mass and machine run time. EPC (pending) opens the door to a completely new level of improved reflow process control.

4. During the heating process of the reflow oven, heat is transferred to the PCB in order to bring all components and materials to the specified temperature process window. The actual temperature during this process results from the PCB to PCB heat transfer rate. There are two factors that affect heat transfer in a reflow oven: air temperature and air flow rate. Closed loop temperature control of a reflow oven is a state of the art requirement but only shows part of the picture - ERSA's EPC shows the whole picture.

Germany Ersa Hotflow 3/20e & 3/20 reflow soldering

Reflow soldering system with high thermal performance and energy balance performance for high-end users.

Ersa reflow soldering uses the proven multi-point nozzle, unique ultra-fine and high-strength internal circulation transmission system, tested high-air-tight furnace tunnel, full closed-loop control of oxygen content and other technical advantages to achieve high thermal efficiency and balanced thermal balance. Characteristics such as extremely low transmission vibration and low N2 consumption provide excellent welding processes and welding quality.

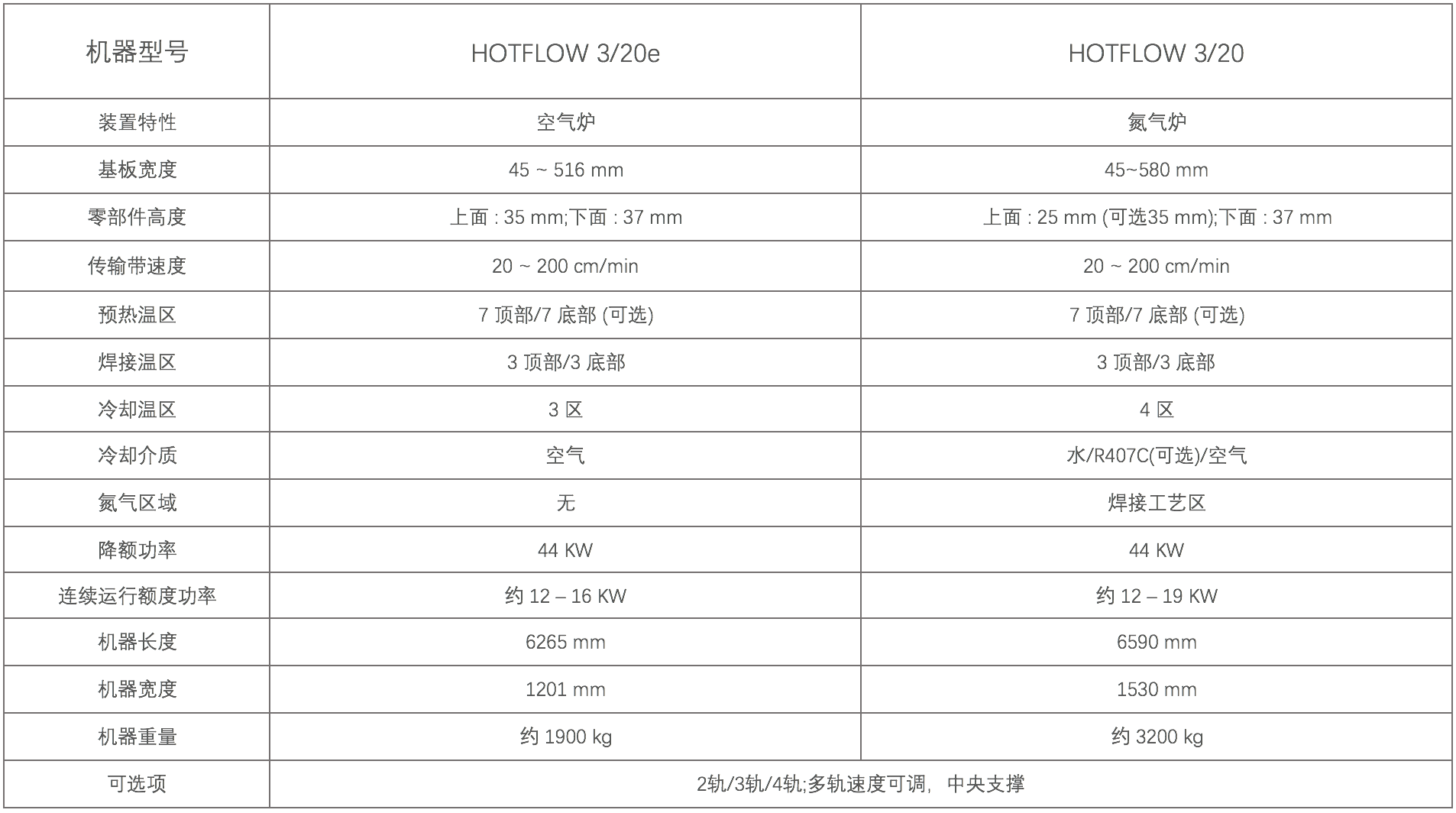

Ersa reflow soldering has only two standard models to ensure good soldering process and welding quality:

1) Hotflow 3/20e (10 temperature zone air furnace)

2) Hotflow 3/20 (10 temperature zone nitrogen furnace)

3. Optional accessories for ERSA reflow HOTFLOW 3/20 products:

1. Nitrogen supply and control system and analyzer 2. Active cooling at the bottom 3. Temperature control and switching internal/external active cooling 4. "Flight" dual-flux management with maintenance 5. Ultra-low mass PCB center support 6 , Multiple rail transit systems 7. ERSA's process control software module 8. ERSA's AutoProfiler software module 9. 17" touch screen 10. ERSA's sensor space shuttle temperature measurement system

135 1032 1270

Contact: Miss Jiang

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

Please submit your request and we will call you right back