MIRTEC MV-6E 3D- AOI

1. South Korea's Meilu Online AOI MV-6E / Meilu Online AOI MV-6E has powerful performance and can detect all materials on the PCB

2. Characters or silk screen printing on the glass chip of mobile phones can be detected

3. PCBA coated with conformal anti-coating paint can be detected

4. South Korea's Milu MV-6E (OMNI) is a complete 3D online optical inspection equipment, equipped with a 15-megapixel high-resolution camera and 8 groups of Moiré stripe lights.

Korean Meilu Online AOI MV-6E functions and features:

01: 3D measurement

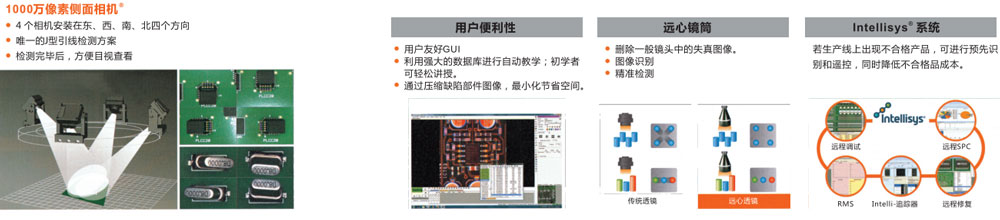

The world's most advanced and accurate measurement technology, the Moire Projection device, measures components from four directions: east, south, west and north to obtain 3D images for safe and high-speed defect detection.

02: 8 groups of moiré fringe projection technology

Digital variable frequency projection technology uses 4 3D emitters to obtain 3D images without blind spots, combines high and low frequency moiré fringes for component height detection, and applies complete 3D detection combined with the main camera.

03.Intellisys connection system

Remote control completely eliminates manpower consumption and improves efficiency. When defects occur in the line, while reducing the cost of defective products, early prevention and remote control become a realistic and feasible solution.

Korean Meilu Online AOI MV-6E product parameters |

model:

MV-6E (OMNI)

PCB size:

50mm×50mm~480mm×460mm

High accuracy:

±3um

Maximum component height:

5mm

2D inspection items:

Missing parts, offset, skewed, tombstone, side-standing, overturned parts, polar opposites, wrong parts, damaged, soldered joints, false soldering, voids, OCR

3D inspection items:

Missing parts, height, position, more tin, less tin, missing solder, double chip, size, IC pin soldering, foreign matter, lifted parts, BGA lifted, tin crawling detection, etc.

FOV field of view:

58.56mm×58.56mm

3D detection speed:

0.80 seconds/FOV/4.260mm²/second

2D detection speed:

0.30 seconds/FOV/10, 716mm²/second

Lens:

telecentric compound lens

Lighting system:

8-segment color lighting system