Benchuang automatic optical detector

Shadow-free high-speed inspection and measurement technology

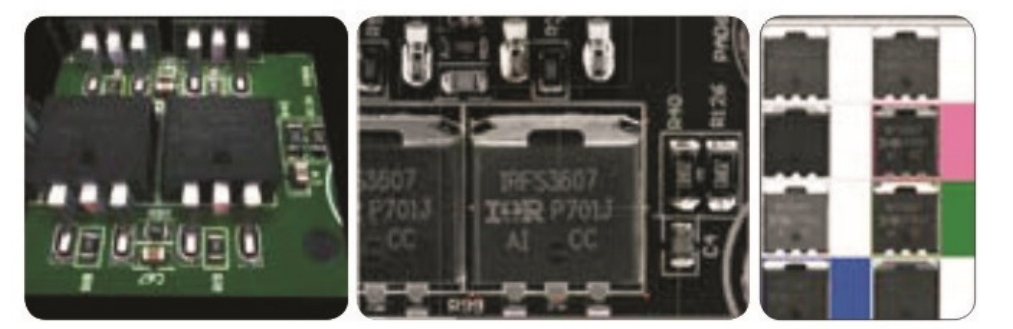

The EAGLE 9 million 8 projection 3D AOI system performs 100% 2D and 3D inspection of PCBs. Guaranteeing completely shadow-free optical inspection and low false alarm rate while maintaining highly flexible system functionality.

High speed detection technology

The EAGLE high-speed option uses an advanced, powerful network processor, controller version and independently developed 9MP 15um 180fps telecentric lens camera that can detect 40.5cm sp.per sec.

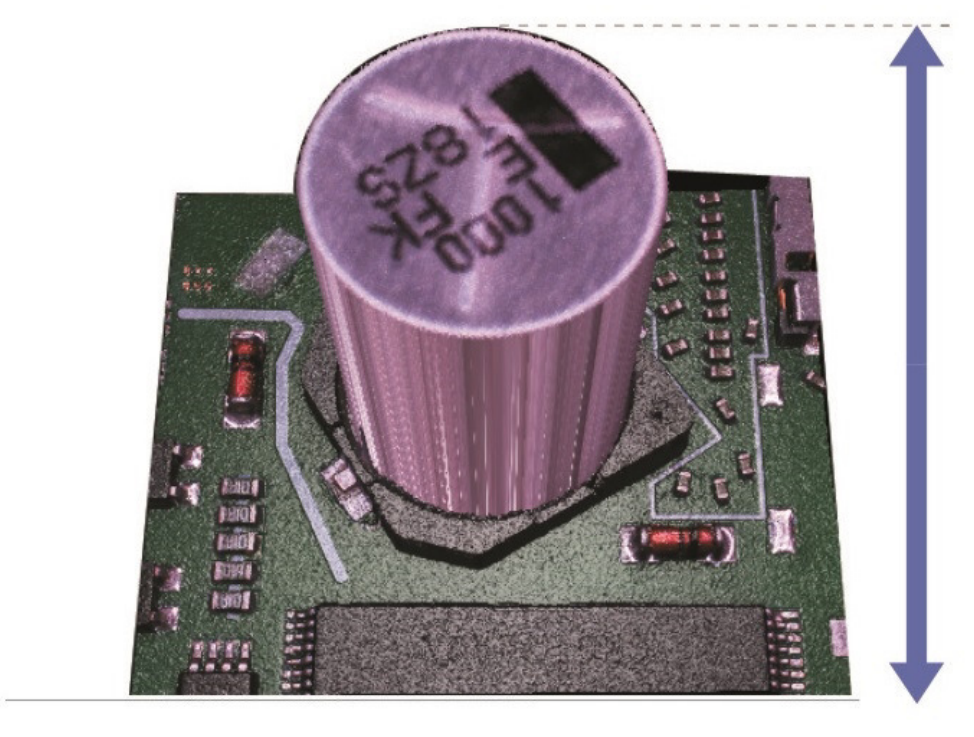

High component detection technology

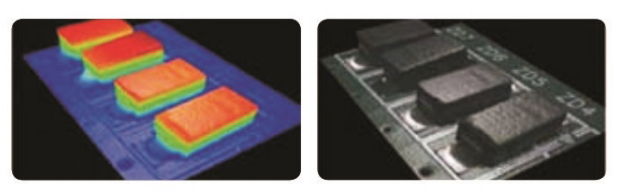

EAGLE's optional new 10-directional 3D projection technology can provide industry-leading all-round 3D inspection of 27mm component height.

3D automatic optical inspection system

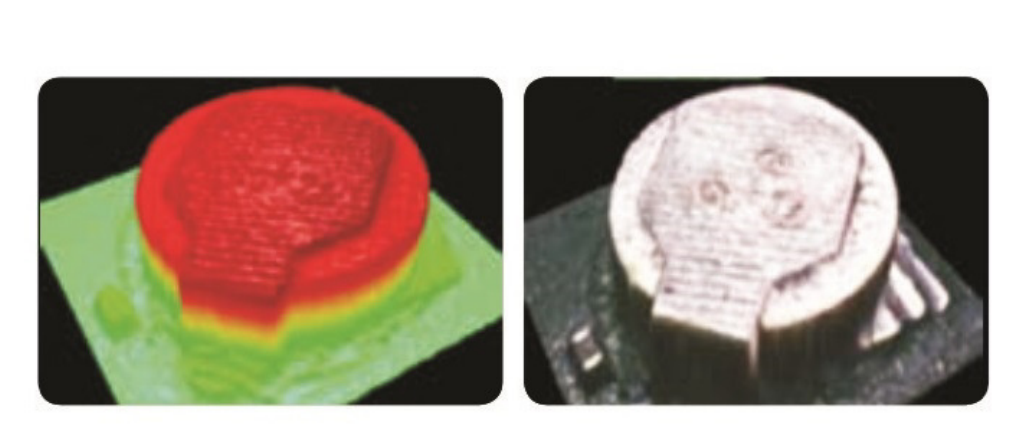

Shadowless 3D technology

Completely eliminate high-density components and the shadows caused by high-density components on the PCB

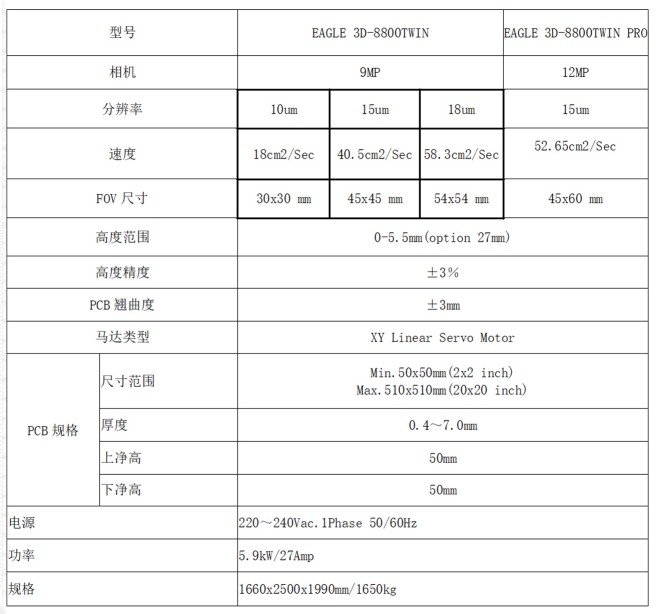

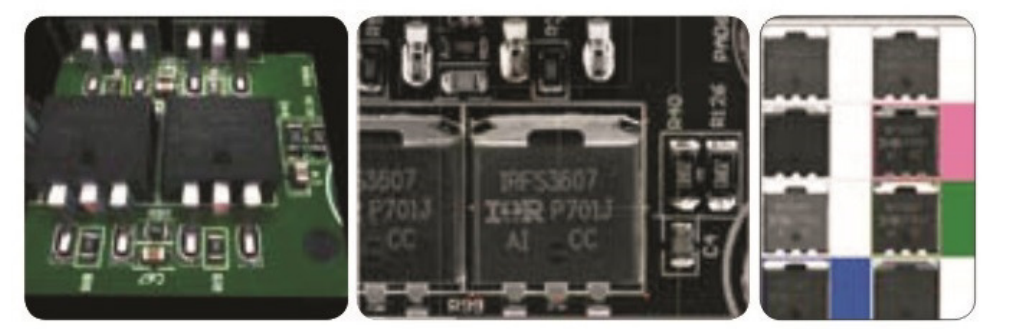

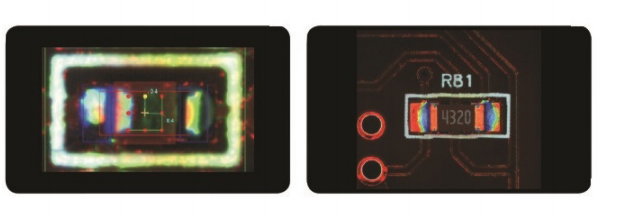

Optical font verification

The principle of optical color extraction and template comparison is used to identify the Part Name of the original. OCR fonts can be added and modified to optimize Part Name detection spare parts and better identify fonts.

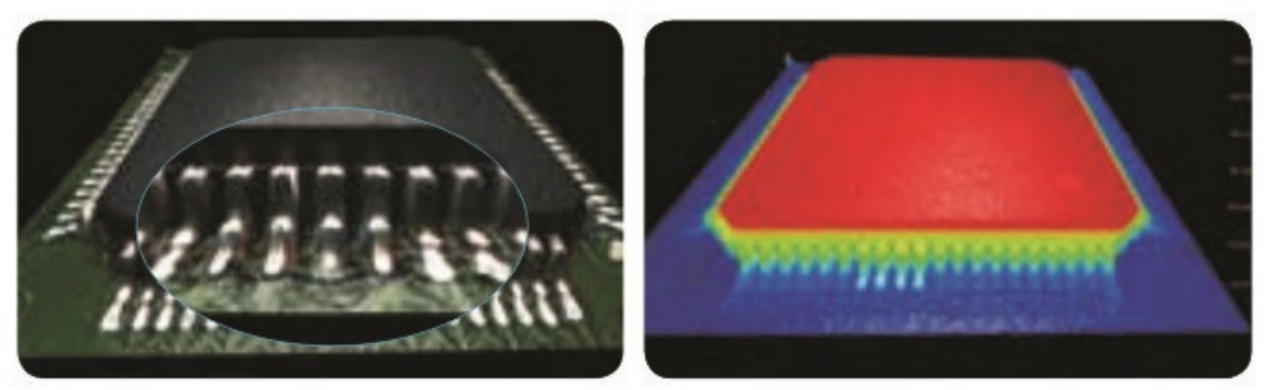

3D pin inspection

EAGLE 3D inspection principle enables pin solder height and volume and improves high quality, true color 3D images

3D solder height measurement

Utilizing our advanced 3D technology, EAGLE 3D AOI is able to detect areas that traditional 2DAOI cannot reach. Test items for solder height, volume and component coplanarity have been added, greatly improving the ability to detect defective products.

2D RGB algorithm

RGB color differentiation makes it easier for operators to distinguish defects such as empty welding and warped pins.

Easy programming (automatic teaching function)

Advanced 3D image processing technology can identify and measure components of any geometric shape and automatically update them into the standard component library. Programming is simple and debugging is fast.

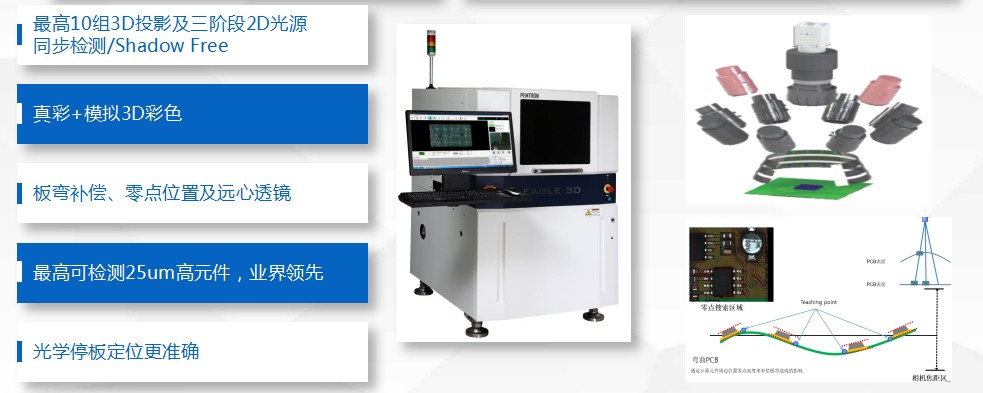

Technical Parameters: