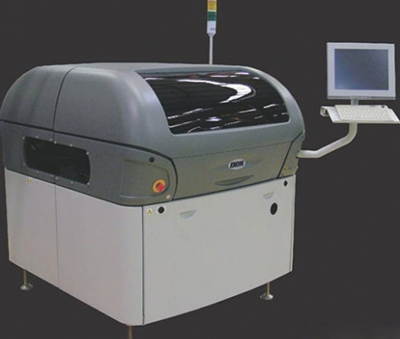

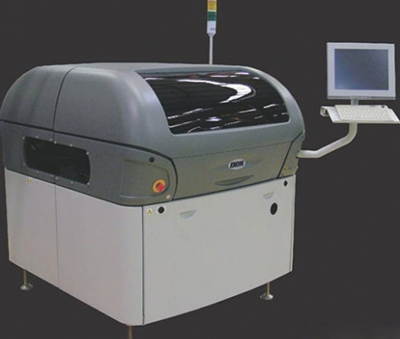

DEK's fully automatic screen printing machine has an advanced top-view/down-view vision system, independently controlled and adjusted lighting, and a high-speed moving lens to accurately align the PCB printed circuit board and the stencil, thereby printing solder paste or red glue. Apply to the printed circuit board according to the openings of the stencil. Ensures printing accuracy of +/-25 micron 6 sigma. High-precision servo motor drive and PC control ensure the stability and precision of printing, as well as the repetitive positioning accuracy of image pattern recognition. The cantilever print head has a specially designed high-rigidity structure. The scraper pressure, speed, and stroke are all controlled by computer servo to maintain uniform and stable printing quality. The scraper beam has a specially optimized structural design, making it lightweight and beautiful in appearance.

Automatic, unassisted stencil bottom cleaning function, programmable control of dry, wet or vacuum cleaning, the cleaning interval can be freely selected, it can completely remove residual solder paste in the mesh to ensure printing quality.

The multifunctional board handling device can automatically position and clamp PCB boards of various sizes and thicknesses, with movable magnetic ejector pins and side clamp devices, which effectively overcomes board deformation and ensures a uniform printing process. It has InstinctivTM V9 operation interface and rich software functions, and has a good human-computer dialogue environment. It is simple to operate, convenient, easy to learn and easy to use. It has the function of self-diagnosing faults with sound and light alarms and prompting the cause of the fault. Can work on single/double-sided PCB printed circuit boards.