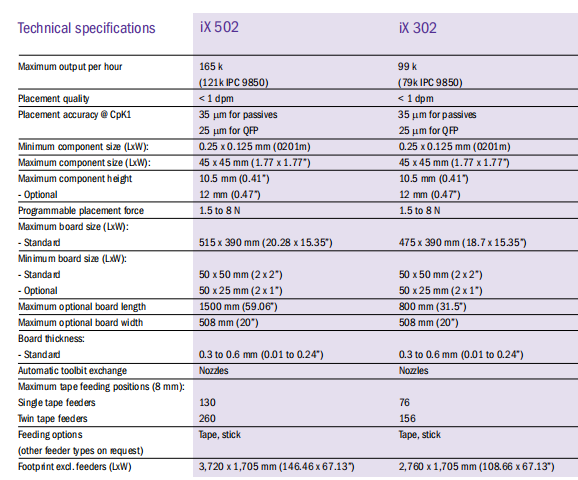

Philips placement machine /K&S high-speed placement machine-iX502 iX302 high-precision placement machine

By continuously strengthening the overall pick-and-place process and introducing a new lightweight feeder, the iX system has a pick-up rate of more than 99.99%, higher placement of passive components (35 microns), and improved camera-aligned component production capacity. 25%.

The unique performance of iX , the industry's best placement control process,

can strictly control every placement, achieving the industry's highest yield rate, thereby lowering costs. High-quality products enable our users to meet the needs of end customers.

The unique mounting process is reflected in:

Conceptually smooth machine movement: low maintenance, reliable component handling and a continuous basis for accuracy, 24 hours a day, 7 days a week - year after year.

Fully software controlled pick and place cycle: controlled pick, optimum acceleration and deceleration process, monitoring and controlled placement: No damage to components.

All individucal placements follow 'blue-print' values, making sure only correct PCBs leave the line.

Proven reliability of fewer than 1 defect per million placement performance.

Capacity can be added or removed in order to increase or decrease output without altering the line footprint: True capacity on demand.