NXTR is a high-end placement machine that takes into account both quality and production efficiency.

Adhering to the design concepts of miniaturization, good productivity per unit area, single-sided operation, modularization, and simple operation,

The corresponding size of the circuit board has been expanded, and the corresponding capabilities of components and data processing capabilities have been enhanced. The successful development of the automatic feeder replacement system frees operators from the constraints of line changing and material replenishment.

NXTR Features

1. "Zero" poor placement

The newly developed sensor technology is used to confirm the status of electronic components and circuit boards and reflect the information to the placement process. This keeps the mounting state in good condition and ensures stable high quality.

2. “Zero” operator

The newly developed intelligent loading vehicle can automatically replenish materials or automatically change lines according to the production schedule. This can completely eliminate short stops caused by various factors (such as operation delays, poor feeding caused by feeding errors).

3. “Zero” downtime

NXTR inherits the modular design concept of NXT. Since no tools are required to replace equipment such as workpieces, maintenance can be performed offline. In addition, preventive maintenance can also be implemented with the help of self-diagnosis function. This can effectively prevent sudden shutdowns that affect production plans.

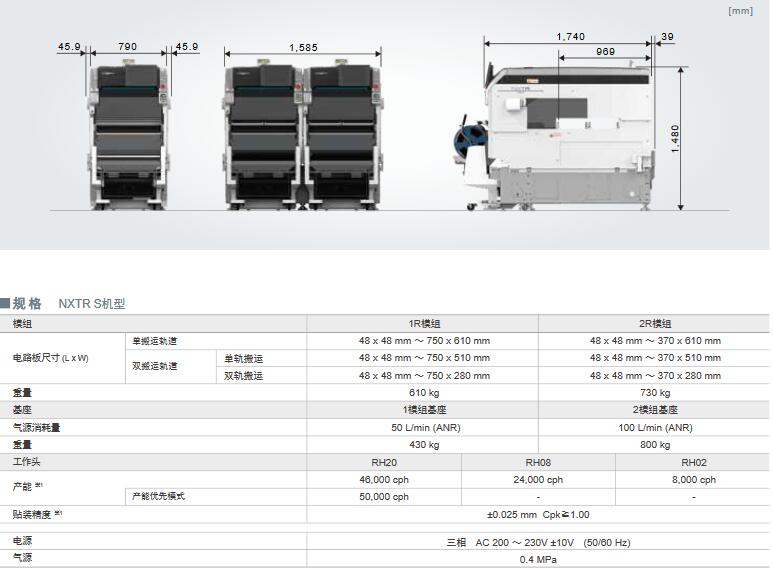

FUJI electronic component placement machine NXTR parameters