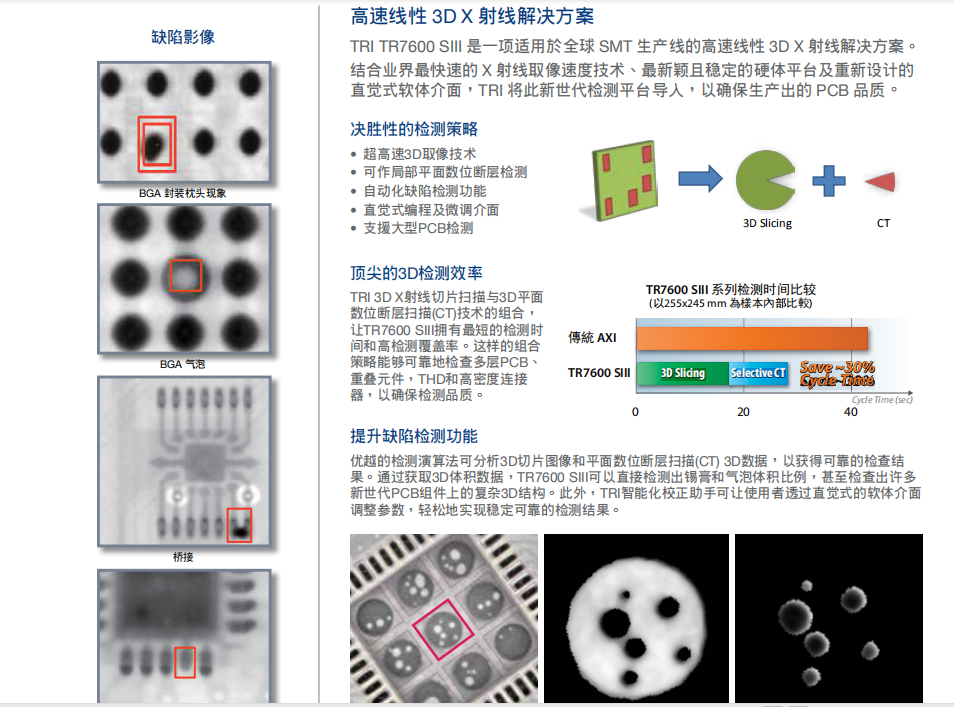

X-RAY TR7600 SIII automatic X-ray inspection machine

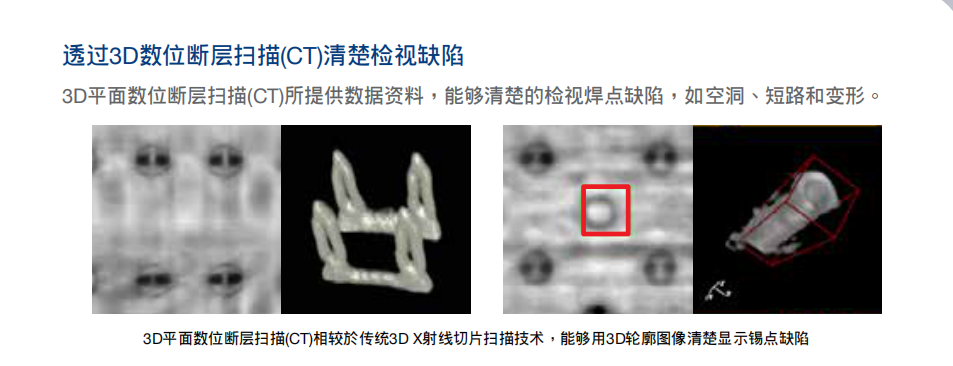

• Ultra-high-speed 3D CT X-ray inspection

• Superior image quality

• Real 3D solder point inspection

• High resolution can detect wafers as small as 01005in

Eliminate board bending problems

TR7600 SIII uses multiple laser sensors to accurately measure any PCB assembly deformation and automatically adjusts component inspection parameters to compensate

Board bends. Reliable inspection results are guaranteed even on circuit boards with overlapping and multi-layer components and heavy-duty press-fit connectors.

Designed for operator safety

Based on the safety design concept, TRI's X-ray inspection system can prevent operator injury or circuit board damage. Complete lead shielding

To prevent exposure to harmful substances in daily work environments and reduce X-ray radiation leakage to less than 0.5 microsieverts per hour.

service centre

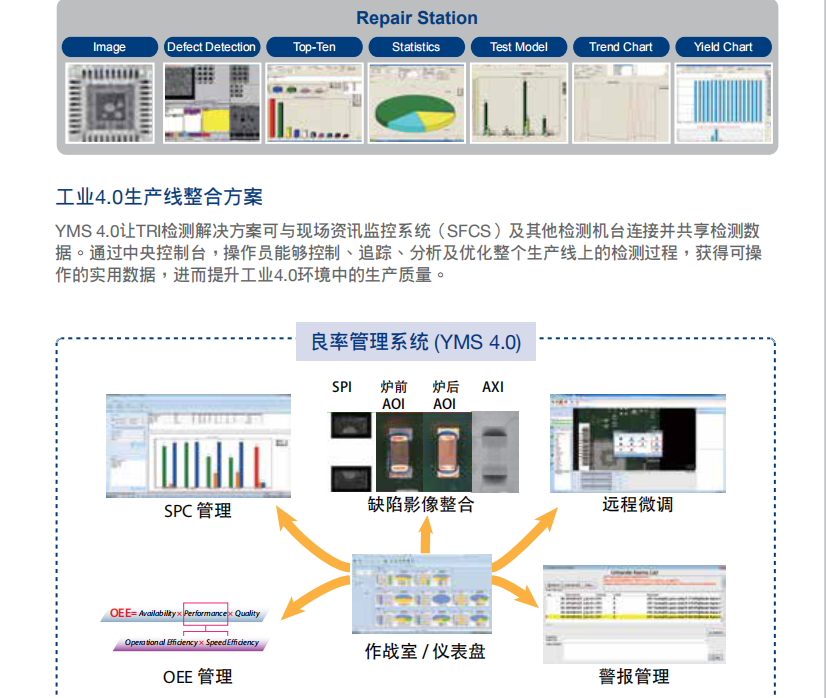

TR7600 SIII can collect various detection information to provide real-time process monitoring and analysis. This integrated approach provides a clear system

Planning and analysis report feedback can improve defect management and increase process yield.