135 1032 1270

Shenzhen Tepu Ke Electronic Equipment Co.,Ltd.

Contact: 135 1032 1270 (Miss Jiang)

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

SMT tape feeder

The SMT tape splicing machine is developed for the SMT automatic production line and the need for quick material change without stopping. It can automatically detect the position of empty material, cut, automatically dock and combine the heads and tails of two rolls of tape with the same specification. Tape wrapped connections. This equipment has its own electrical system, is lightweight, has high connection accuracy, has a pass rate of over 90 to 95%, automatically collects materials after connection, and has universal interfaces.

Device parameters:

Applicable tape range: tape width 8mm, thickness 0.25~1.2mm

Machine cycle (C/T): 8S (time adjustable)

Battery capacity: 60AH (optional) Power supply time: more than 12 hours

Code reading range: one-dimensional code or two-dimensional code (optional)

Operating system: Win7

Communication expansion: can be seamlessly connected with the production system MES or SFCS

Working height: about 900mm

Power supply: comes with lithium battery (equipment comes standard with 2PCS)

Empty material detection range: British 0201 or above components can automatically detect empty materials.

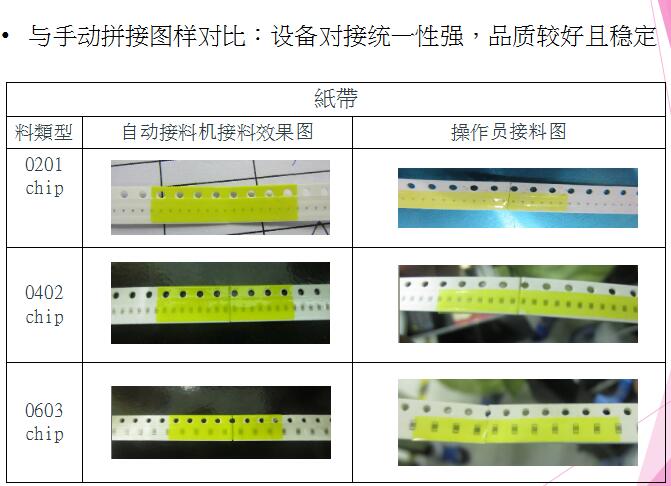

Schematic diagram of splicing effect

Equipment function introduction and advantages:

1. The pre-cutting mechanism cuts off excess empty materials, saving time in detecting empty materials and avoiding manual handling of scissors repeatedly, saving man-hours.

2. The equipment is simple to operate and takes a short time to get started (new employees can operate it proficiently in 15 minutes of training), which reduces the company's training costs for employees. At present, employee mobility is high, and the reliance on employees' technology is reduced to an even lower level.

3. The equipment has high splicing accuracy. The material spacing of the joints can be guaranteed to be 4MM or 2MM. The nozzle of the placement machine is sucked at the center of the component when sucking the components. This can improve the placement quality and reduce the throw rate, and reduce the space of the placement machine. Number of refills.

4. The equipment's material receiving time is more than 1 to 2 times faster than manual (skilled) material receiving, which can effectively reduce working hours and reduce employee labor intensity.

5. The improvement of equipment splicing quality can effectively reduce patch downtime caused by splicing quality and increase the equipment transfer rate by more than 5%.

Can solve the following problems for customers

Save management costs:

The pre-cutting mechanism cuts off excess empty materials, saving time in detecting empty materials and avoiding manual handling of scissors repeatedly, saving man-hours. With the function of MES onboard comparison of data, it can also significantly reduce comparison time and reduce errors.

Reduce labor costs:

The equipment is simple to operate and takes a short time to get started (new employees can operate proficiently in 15 minutes of training), which reduces the company's training costs for employees. At present, employee mobility is high, and the reliance on employees' technology is reduced to a lower level; the equipment takes more time to receive materials than manual labor (skilled workers) ) The speed of receiving materials is more than 1~2 times faster, which can effectively reduce working hours and reduce the labor intensity of employees.

Improve equipment mobility:

The improved material splicing quality of the equipment can effectively reduce the short downtime of the patch due to the splicing quality, and improve the equipment's grafting rate by more than 5%. The equipment splicing accuracy is high, and the material spacing of the joints can be guaranteed to be 4MM or 2MM. The nozzle of the chip machine sucks at the center of the component when sucking the component, which can improve the quality of the chip, reduce the throw rate, and reduce the number of empty refills of the chip mounter.

Comparison of the effects of equipment picking up materials and manual picking up materials

135 1032 1270

Contact: Miss Jiang

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

Please submit your request and we will call you right back